Designing Possibilities: 35 Years of R&D Advancements

"It’s the moment where you are faced with a blank page and there is a sea of possibilities. The ‘what-if’ moment is precious, as it is quite short-lived. Balancing users' needs, the project lead times, and the costs all add to the excitement of solving the problem.”

Since Limbs & Things originated from Margot Cooper’s kitchen tabletop, our company has been designing, engineering, and producing our products from scratch. Born from ideas formed with medical experts across the globe, our simulation continues to bring novel and innovative training to the medical simulation world.

Heavy investment in our research and development has allowed us to continue to be leaders in medical simulation. Currently comprising of 36 design experts, our R&D team collaborates with external medical professionals to bring each of our models to life.

Pete D’Alessandro has been Head of our R&D team for 18 years and has over seen some of our biggest projects including the Cardiovascular and Respiratory Examination (CaRE) Trainer, our most complex model to date. We talked with Pete about our process to understand what makes R&D at Limbs & Things so exciting and unique.

“When we get given the initial project brief, a combination of elements kick into motion. Firstly, we work collaboratively with the Product Managers to understand the users' requirements and build an understanding of how the product will embody these features. The fun, creative bit begins with feasibility studies, proof of concept mock-ups, early design drawings, and mapping the functional anatomy.

There are several sections of the process that are very exciting. The first is obvious, it’s the moment where you are faced with a blank page and there is a sea of possibilities. The ‘what-if’ moment is precious, as it is quite short-lived. Balancing users' needs, the project lead times, and the costs all add to the excitement of solving the problem.

The second is when prototypes become products. The nature of NPD (New Product Development) leaves the fine-tuning until the latter stages. But once this happens, the product snaps into clear focus and the time we have taken to work through each problem is evident in the finished product.

We always look for ways to enhance the products by them being able to do something a human can’t. This sounds odd but not seeing the fixed nature of human anatomy or physiology as a constraint, but as an opportunity to play with how different conditions can be presented, is very liberating.”

As our company has evolved over the years, so has our R&D process. This year we celebrate Limbs & Things’ 35th birthday, a milestone we’ve reached partly thanks to our constant innovation and modernisation of our R&D.

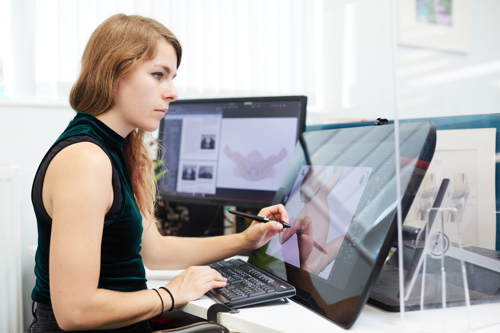

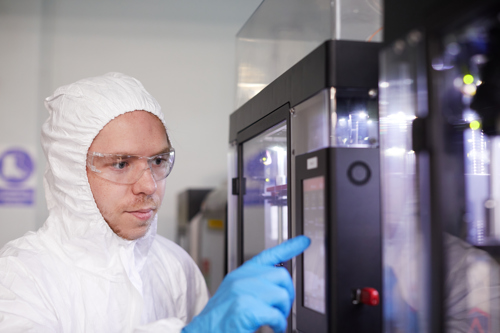

“The evolution of the NPD process has been a big part of my job. Initially, when I created the first version of this back in 2009, we had 12 phases; this has been carefully whittled down to a streamlined and efficient 6 stage process. The utilisation of Computer Aided Design (CAD) and 3D printing has improved the quality and robustness of our products giving us precision at every stage of development.

Developing electromechanical products, like CaRE has allowed us to build our Systems & Software Team and solve complex technical problems, such as synchronising pulses and heart sounds.

Additionally, having a Medical Artist Team provides us with the building blocks for each product, previously, we had to use anatomy textbooks and trips to the anatomy rooms to gain an understanding of how it all works. Transferring anatomical structures into CAD took months, now this is done in a couple of weeks.”

Ensuring that our products are designed for supporting precise medical training is essential, so we always include consultation with experts in the field at every step of the process.

“When creating the original design for PROMPT Flex Birthing Simulator between 2001 – 2003, we collaborated with the Southmead Hospital Team, mainly Tim Draycot and Cathy Winters. We were able to take their ideas and needs and create something that made a real impact in reducing negative outcomes for babies who experience shoulder dystocia.

More recently, working on CaRE, we knew the heart & lung sounds and pulse movements had to be synchronised, but it posed a major challenge for the R&D team. Seeing our Resident Clinician Dr Andy Griffiths nodding as he moved the LimbPad over the model while feeling the pulse, realising we had cracked it, was a great moment.”

Did you like this article?

Share it on social media, and remember to tag us!